Volvo XC60: Tire Sealing System

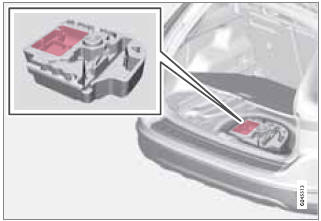

Location

Location

Introduction

Certain models are equipped with a tire sealing system* that enables you to temporarily seal a hole in the tread surface and re-inflate a flat tire, or to adjust a tire’s inflation pressure.

The system consists of an air compressor, a container for the sealing compound, wiring to connect the system to the vehicle’s electrical system via one of the 12-volt sockets, and a hose used to connect the system to the tire’s inflation valve.

The 12-volt sockets are located in the front tunnel console, on the rear side of the center console in the rear seat and in the cargo area*, see page 200.

Accessing the tire sealing system

The tire sealing system is stowed under the floor of the cargo area. To access it:

1. Lift the floor hatch in the cargo area.

2. Lift out the tire sealing system.

NOTE

• The tire sealing system is only intended

to seal holes on the tire’s tread area, not

the sidewall.

• Tires with large holes or tears cannot be

repaired with the tire sealing system.

• After use, stow the tire sealing system

properly to help prevent rattling.

WARNING

• After using the tire sealing system, the

vehicle should not be driven farther than

approximately 120 miles (200 km).

• Have the tire inspected by a trained and

qualified Volvo service technician as

soon as possible to determine if it can

be permanently repaired or must be

replaced.

• The vehicle should not be driven faster

than 50 mph (80 km/h) while using a tire

that has been temporarily repaired with

the tire sealing system.

• After using the tire sealing system, drive

carefully and avoid abrupt steering

maneuvers and sudden stops.

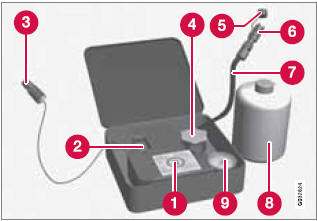

Tire sealing system–overview

1 Speed limit sticker

2 On/Off switch

3 Electrical wire

4 Bottle holder (orange cover)

5 Protective hose cover

6 Air release knob

7 Hose

8 Bottle with sealing compound

9 Air pressure gauge

WARNING

Please keep the following points in mind

when using the tire sealing system:

• The sealing compound bottle (no. 8 in

the illustration) contains 1.2-Ethanol

and natural rubber-latex. These substances

are harmful if swallowed.

• The contents of this bottle may cause

allergic skin reactions or otherwise be

potentially harmful to the skin, the central

nervous system, and the eyes.

Precautions:

• Keep out of reach of children.

• Do not ingest the contents.

• Avoid prolonged or repeated contact

with the skin.

• Hands should be washed thoroughly

after handling.

First aid:

• Skin: Wash affected areas of skin with

soap and water. Get medical attention

if symptoms occur.

• Eyes: Flush with plenty of water for least

15 minutes, occasionally lifting the

upper and lower eyelids. Get medical

attention if symptoms occur.

• Inhalation: Move the person to fresh air. If irritation persists, get medical

attention.

NOTE

Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.

Tire sealing system–temporarily repairing a flat tire

Tire sealing system–temporarily repairing a flat tire

Temporarily repairing a flat tire is done in two stages:

• Stage 1: The hole is sealed by pumping sealing compound into the tire. The car is then driven a short distance to distribute the sealing compound in the tire.

NOTE

Do not remove any foreign objects (nails,

etc.) from the tire before using the sealing

system.

• Stage 2: The tire’s inflation pressure is checked and adjusted if necessary.

WARNING

• Never leave the tire sealing system

unattended when it is operating.

• Keep the tire sealing system away from

children.

• Be sure the vehicle is parked safely off

the road and away from moving traffic.

• Apply the parking brake.

Stage 1: Sealing the hole

1. Open the cover on the tire sealing kit.

2. Peel off the speed limit sticker and affix it to the steering wheel hub where it will be clearly visible to the driver.

3. Ensure that the on/off switch is in position 0 (the 0 side of the switch should be pressed down).

WARNING

Contact with the sealing compound may

cause skin irritation. If contact occurs, wash

the affected area immediately with soap and

water.

4. Unscrew the orange cover over the bottle holder and unscrew the cap on the bottle of sealing compound.

NOTE

Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.

5. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep

it securely in place and help prevent sealing

compound leakage. Once in place, the bottle

cannot be unscrewed. This must be done

by a trained and qualified Volvo service

technician.

6. Remove the valve cap from the tire’s inflation valve and screw the tire sealing system’s hose connector onto the valve as tightly as possible by hand.

7. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

8. Start the vehicle’s engine.

WARNING

The vehicle´s engine should be running

when the tire sealing system is used to avoid

battery drain. Therefore, be sure the vehicle

is parked in a well ventilated place, or outdoors,

before using the system.

9. Start the tire sealing system’s compressor by pressing the on/off switch to position I.

WARNING

• Never stand next to the tire being inflated

when the compressor is in operation.

• If cracks, bubbles, etc. form on the tire,

switch off the compressor immediately.

• If there is visible damage to the sidewall

or the rim, the tire cannot be repaired.

The vehicle should not be driven if this

occurs. Contact a towing service or

Volvo On Call Roadside Assistance if

applicable.

NOTE

The air pressure gauge will temporarily

show an increase in pressure to approximately

88 psi (6 bar) while the sealing compound

is being pumped into the tire. The

pressure should return to a normal level

after approximately 30 seconds.

10. Within seven minutes, inflate the tire to between 22—44 psi (1.8—3.0 bar). Switch off the compressor briefly to get a clear reading from the pressure gauge.

CAUTION The compressor should not be used for more than 10 minutes at a time to avoid overheating.

WARNING

If the pressure remains below 22 psi

(1.8 bar) after approximately seven minutes,

turn off the compressor. In this case, the

hole is too large to be sealed and the vehicle

should not be driven.

11. Switch off the compressor and disconnect the electrical wire from the 12-volt socket.

12. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

13. Immediately drive the vehicle for approximately 2 miles (3 km) at a maximum speed of 50 mph (80 km/h) to distribute the sealing compound in the tire.

CAUTION

If your vehicle is equipped with the Tire

Pressure Monitoring System (TPMS), the

use of the sealing compound may lead to

incorrect tire pressure readings or in rare

cases, damage to the tire pressure sensor.

Use the tire sealing system to check and

adjust the damaged tire's inflation pressure.

NOTE

• Safely stow the tire sealing system in a

convenient place as it will soon be used

again to check the tire’s inflation pressure.

• The empty bottle of sealing compound

cannot be removed from the bottle

holder. Consult a trained and qualified

Volvo service technician to have the

bottle removed and properly disposed

of.

WARNING

If heavy vibrations, unsteady steering

behavior, or noises should occur while driving,

reduce speed and park the vehicle in a

safe place. Recheck the tire for bumps,

cracks, or other visible damage, and

recheck its inflation pressure. If the pressure

is below 19 psi (1.3 bar), do not continue

driving. Have the vehicle towed to a trained

and qualified Volvo service technician.

Stage 2: Checking inflation pressure

1. Connect the tire sealing system as described in stage 1.

2. Refer to the inflation pressure table in this chapter for the correct inflation pressure. If the tire needs to be inflated, start the tire sealing system’s compressor. If necessary, release air from the tire by turning the air release knob counterclockwise.

CAUTION The compressor should not be used for more than 10 minutes at a time to avoid overheating.

WARNING

If you interrupt your trip for more than 1

hour, check the inflation pressure in the

damaged tire again before continuing.

Replacing the sealing compound container

The sealing compound container must be replaced if:

• the tire sealing system has been used to repair a tire.

• the container’s expiration date has passed (see the date on decal).

NOTE

• After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replacement

parts.

• If the sealing compound bottle’s expiration

date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances.

Inflating tires

The tire sealing system can be used to inflate the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position 0 (the 0 side of the switch should be pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s inflation valve and screw the hose connector onto the valve as tightly as possible by hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

6. Start the vehicle’s engine.

WARNING

• The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the system.

• Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the gauge. Switch off the compressor briefly to get a clear reading from the pressure gauge.

8. Refer to the tire inflation table in this chapter for the correct inflation pressure. If the tire needs to be inflated, start the tire sealing system’s compressor (press the on/off switch to position I). If necessary, release air from the tire by turning the air release knob counterclockwise.

CAUTION The compressor should not be used for more than 10 minutes at a time to avoid overheating.

9. Turn off the compressor (press the on/off switch to position 0) when the correct inflation pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

11. Disconnect the electrical wire from the 12-volt socket.

See also:

Remote engine start system (dealer option)

- Do not remote start a vehicle in

an enclosed environment (e.g., in

a closed garage). Prolonged operation

of a motor vehicle in an

enclosed environment can cause

a harmful build-up of Carbon

Monoxide. Carbon Monoxide is

harmful to ...

Media Center 230 (REQ) — AM/FM Stereo Radio And 6–Disc CD/DVD Changer (MP3/WMA

AUX Jack)

NOTE: The radio sales code is located on the lower right

side of the radio faceplate.

Media Center 230 (REQ) ...

Temporary Spare

Temporary Spare